{

“@type”: “Article”,

“author”: {

“url”: “https://htexs.com”,

“name”: “Htexs”,

“@type”: “Organization”

},

“@context”: “https://schema.org”,

“headline”: “PERC Solar Cell Explained: Efficiency, Benefits, and Uses”,

“publisher”: {

“url”: “https://htexs.com”,

“name”: “Htexs”,

“@type”: “Organization”

},

“inLanguage”: “en”,

“articleBody”: “PERC solar cell comprehensive guide covers working principle, types, efficiency gains, real-world applications, and comparisons with other solar technologies.”,

“description”: “PERC solar cell comprehensive guide covers working principle, types, efficiency gains, real-world applications, and comparisons with other solar technologies.”,

“datePublished”: “2025-10-17T00:26:24.288Z”

}

Over 80 percent of new solar panels worldwide now use PERC technology, a striking jump that highlights the demand for higher efficiency. As global energy needs surge, the way we harvest sunlight matters more than ever. Advances in PERC solar cells are making solar power not just more powerful, but also more practical for homes and businesses wanting reliable clean energy.

Key Takeaways

| Point | Details |

|---|---|

| PERC Technology Enhances Efficiency | PERC solar cells improve energy conversion efficiency from over 17% to above 21%, significantly optimizing solar energy output. |

| Versatile Applications | PERC cells are adaptable for various installations, including residential, commercial, and utility-scale solar projects, enhancing overall energy generation. |

| Key Advantages and Challenges | While offering high efficiency and better performance under different conditions, PERC technology may face higher manufacturing costs and risks of degradation. |

| Main Variations of PERC Cells | PERC technology includes monocrystalline and polycrystalline types, with Selective Emitter designs boasting efficiencies exceeding 22% and reduced losses. |

Table of Contents

- Defining Perc Solar Cell Technology

- How Perc Cells Boost Efficiency And Output

- Main Types Of Perc Cells And Variations

- Applications And Integration In Solar Systems

- Advantages, Limitations, And Key Comparisons

Defining PERC Solar Cell Technology

Imagine a solar technology that squeezes more energy out of every single sunlight ray. That’s the magic of PERC solar cell technology. PERC, which stands for Passivated Emitter Rear Contact, represents a breakthrough in solar panel design that dramatically improves energy conversion efficiency.

At its core, PERC technology introduces a clever engineering solution: a thin dielectric passivation layer on the rear side of solar cells. According to research from solar engineering studies, this specialized layer does something remarkable – it reflects unabsorbed light back into the cell, giving photons a second chance to generate electricity. Read more about solar cell innovations to understand how this impacts renewable energy design.

The performance boost is significant. Traditional crystalline silicon solar wafers typically achieved efficiency rates just over 17%, but with PERC technology, those rates have jumped to over 21%. Key advantages of this approach include:

- Reduced electron recombination losses

- Enhanced light reflection and absorption

- Improved overall solar panel performance

- Cost-effective manufacturing process

Today, PERC technology isn’t just a laboratory curiosity – it’s become mainstream. Approximately 80% of global solar panels now incorporate PERC design principles, transforming how we capture and convert solar energy into electricity.

This widespread adoption underscores the technology’s proven effectiveness and potential to make renewable energy more accessible and efficient.

This widespread adoption underscores the technology’s proven effectiveness and potential to make renewable energy more accessible and efficient.

How PERC Cells Boost Efficiency and Output

When it comes to solar technology, every percentage point of efficiency matters. PERC solar cells represent a game-changing approach that dramatically improves energy conversion by solving fundamental performance challenges. Learn more about emerging solar technologies to understand the broader context of these innovations.

According to research from solar energy experts, PERC technology increases panel efficiency by approximately 1 to 1.5 percentage points compared to conventional solar cells. This might sound small, but in the world of solar energy, it’s a significant leap. Traditional solar panels typically operate around 18% efficiency, but PERC designs push that threshold to nearly 21%, representing a substantial improvement in energy generation.

The secret behind this efficiency boost lies in PERC’s innovative design. By introducing a specialized passivation layer on the rear surface, these solar cells achieve multiple performance enhancements:

- Reduced Electron Recombination: Minimizes energy loss at the cellular level

- Enhanced Light Trapping: Reflects unabsorbed light back into the silicon

- Improved Temperature Performance: Maintains higher efficiency under heat stress

- Better Low-Light Responsiveness: Generates more electricity during cloudy or partial shade conditions

These technological improvements aren’t just theoretical. Real-world applications demonstrate that PERC cells provide more consistent and reliable energy output across diverse environmental conditions. The rear-surface passivation doesn’t just incrementally improve performance – it fundamentally transforms how solar panels capture and convert sunlight into electrical energy.

Main Types of PERC Cells and Variations

The world of PERC solar cell technology isn’t a one-size-fits-all solution. In fact, it offers several nuanced variations tailored to different solar panel manufacturing needs and performance requirements. Explore more about solar cell innovations to understand the broader technological landscape.

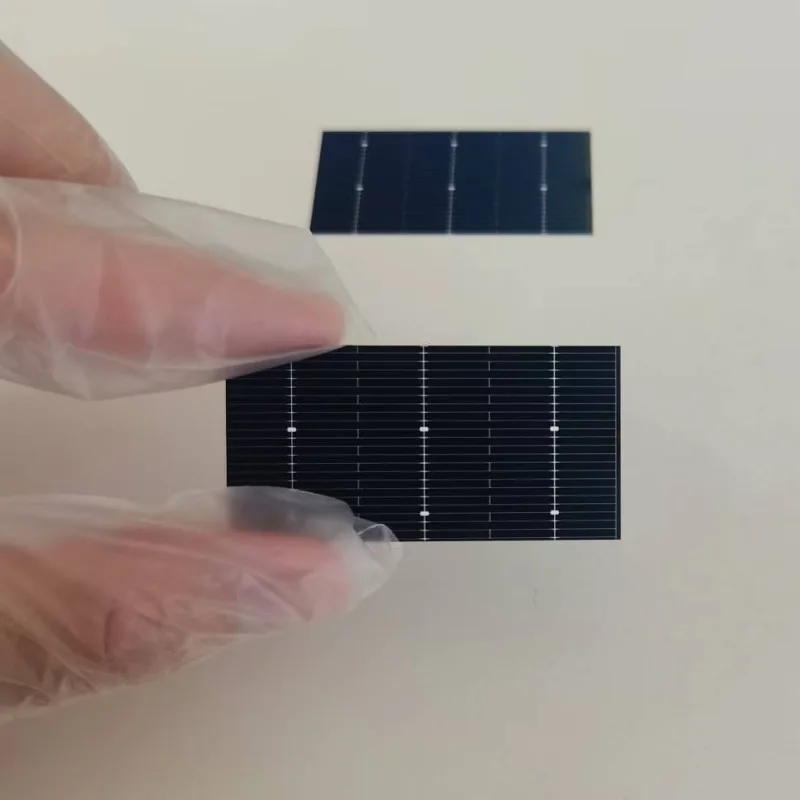

According to solar manufacturing research, PERC technology primarily exists in two fundamental crystalline configurations: monocrystalline and polycrystalline cells. Both leverage dielectric materials like aluminum-oxide and silicon-nitride to enhance light absorption and energy conversion. The key difference lies in their crystal structure and manufacturing process, which influences overall panel performance and cost-effectiveness.

Among the most innovative PERC variations is the PERC SE (Selective Emitter) design, which represents a significant leap in solar cell engineering. This advanced configuration combines traditional PERC principles with a Shingled Emitter approach, creating unique performance advantages:

- Segmented cell design with overlapping strips

- Reduced shading and resistive losses

- Enhanced power output

- Improved durability and reliability

- Higher efficiency ratings (exceeding 22%)

The versatility of PERC technology means manufacturers can optimize solar panels for specific environmental conditions. Whether dealing with low-light scenarios, high-temperature regions, or space-constrained installations, these cell variations provide targeted solutions that push the boundaries of solar energy efficiency. By continuously refining these designs, researchers are transforming solar technology from a promising alternative to a mainstream energy solution.

Here’s a comparison of the main PERC cell types and variations:

![]()

| Cell Type | Structure | Efficiency Range | Key Advantages |

|---|---|---|---|

| Monocrystalline PERC | Single-crystal silicon | 21-23% | High efficiency Long lifespan |

| Polycrystalline PERC | Multi-crystal silicon | 20-21% | Lower cost Good performance |

| PERC SE (Selective Emitter) | Shingled segmented emitter | 22%+ | Maximum efficiency Minimized losses |

Applications and Integration in Solar Systems

PERC solar cell technology isn’t just a laboratory breakthrough – it’s transforming how we design and deploy solar energy solutions across multiple sectors. Discover more about solar innovation strategies to understand the broader technological landscape.

According to research in solar energy deployment, PERC cells have proven particularly versatile, finding applications across diverse environments. From residential rooftops to massive utility-scale solar farms, these advanced solar cells offer unprecedented flexibility. The key advantage lies in their ability to perform consistently under challenging conditions, making them ideal for space-constrained or variable climate installations.

The practical applications of PERC technology span several critical sectors:

- Residential Installations: Perfect for home solar systems with limited roof space

- Commercial Buildings: Enables large-scale energy generation with compact panel designs

- Utility-Scale Solar Farms: Maximizes energy yield in expansive solar field deployments

- Remote Power Systems: Provides reliable electricity in off-grid locations

- Agricultural Solar Setups: Supports sustainable farming energy solutions

What makes PERC cells truly revolutionary is their adaptability. Whether facing partial shading, high temperatures, or complex installation geometries, these solar cells maintain superior performance. By delivering higher energy yields and more consistent output, PERC technology is bridging the gap between renewable energy potential and practical, widespread implementation. The future of solar energy isn’t just about generating electricity – it’s about doing so more efficiently, reliably, and strategically than ever before.

Advantages, Limitations, and Key Comparisons

PERC solar cell technology represents a significant leap forward, but like any technological innovation, it comes with its own set of pros and cons. Understanding these nuances is crucial for making informed decisions about solar energy investments. Explore comparative solar technologies to gain deeper insights into the evolving renewable energy landscape.

According to research in photovoltaic technology, PERC cells offer remarkable advantages that set them apart from traditional solar technologies. With efficiency ratings ranging between 20% and 23%, these cells significantly outperform conventional designs. Their enhanced performance stems from improved low-light responsiveness and a reduced temperature coefficient, which translates to more consistent energy generation across diverse environmental conditions.

However, the technology isn’t without its limitations. Key challenges include:

- Higher Manufacturing Costs: More complex production processes increase initial investment

- Light-Induced Degradation (LID): Potential performance reduction during initial exposure

- Potential Induced Degradation (PID): Risk of gradual efficiency loss over time

- Heat Accumulation: Enhanced light trapping can lead to thermal management challenges

- Regional Availability Constraints: Limited manufacturing capacity in some markets

Compared to traditional solar cell technologies, PERC represents a significant optimization. While the advanced design comes with slightly higher upfront costs, the long-term benefits of increased energy yield and improved reliability often outweigh these initial investments. The solar industry continues to refine PERC technology, addressing limitations and pushing the boundaries of what’s possible in renewable energy generation.

Find Your Next Solar Edge with HTEXS

Are you visiting this article because you want greater solar efficiency but feel overwhelmed by technical details like PERC technology, degradation rates, or manufacturing costs? If you want answers on how to make smarter choices for energy savings, reliable solar performance, and future-ready living, you are not alone. Our Tips And Techniques section breaks down solar trends and practical solutions, making complex innovations simple and actionable.

If you are ready to make your solar experience easier, start by exploring honest product reviews and step-by-step guides at HTEXS. Get clear, trustworthy insights on the best ways to maximize PERC cell advantages, avoid common installation pitfalls, and stay ahead of new solar breakthroughs. Do not wait for the industry to pass you by. Visit HTEXS now and power your next purchase with confidence.

Frequently Asked Questions

What is PERC solar cell technology?

PERC solar cell technology, or Passivated Emitter Rear Contact, enhances traditional solar cells by adding a passivation layer on the rear side, which reflects unabsorbed light back into the cell, improving energy conversion efficiency.

How does PERC technology improve solar panel efficiency?

PERC technology boosts solar panel efficiency by approximately 1 to 1.5 percentage points compared to conventional solar cells, increasing energy generation from around 18% to nearly 21%.

What are the main types of PERC solar cells?

The main types of PERC solar cells are monocrystalline and polycrystalline cells, which differ in crystal structure. An advanced variation is the PERC SE (Selective Emitter), which offers higher efficiency ratings and reduced losses.

What are the advantages and limitations of PERC solar cell technology?

PERC solar cells provide higher efficiency, improved low-light performance, and greater reliability. However, they may also incur higher manufacturing costs and risks of light-induced degradation and heat accumulation.

Recommended

- Understanding Solar Cell Technology: How It Works – htexs.com

- Solar Panel Efficiency: Everything You Need to Know – htexs.com

- Complete Guide to Solar Innovation Explained – htexs.com

- Understanding the Solar Benefits: Harnessing Energy Power – htexs.com